CO2 Onboard

Our aim is to achieve carbon-neutral energy systems with minimal disruption to the existing infrastructure, while simultaneously closing the emissions loop from fuel production to utilization.

We focus on developing power trains for large transportation applications and stationary power generation systems, which enable net-zero and even net-negative emissions.

*(Please use the vertical arrows at lower-right corner, to see 'Current Problems')

Inefficiencies of fuels further made worse by the manner of usage

Current plans for the future include using:

- Bio-Methanol (Syn-Gas from Biomass/Biogas)

- Bio-E-Methanol (Bio-mass based Syn-Gas + Green Hydrogen)

- E-Methanol (Direct Air Capture/Carbon Capture from Coal plant, etc. + Green Hydrogen)

- Blue-Methanol

- Blue-Ammonia

- Green-Ammonia

- and other Methanol/non-Methanol derivatives such as Jet Fuel, Sustainable Aviation Fuels, etc. in Combustion engines.

This approach is inefficient in terms of energy and cost. Additionally, emissions (not just CO2 but NOx, Contrails, PM, etc.) still end up in the atmosphere.

*(Please scroll down using arrows)

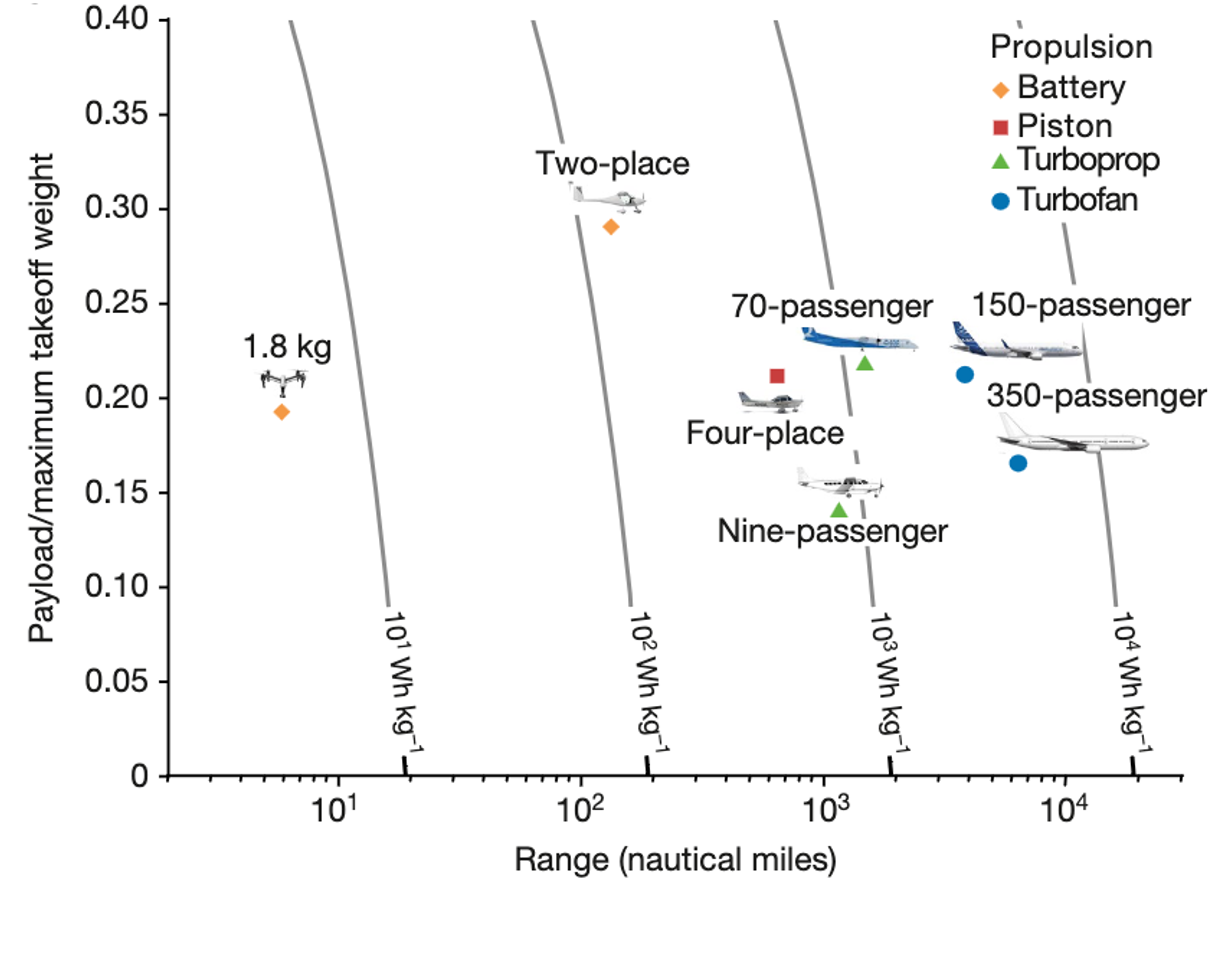

Batteries do not scale well with size (at least for now)

The image above, sourced from Viswanathan et al. (2022), illustrates that for a hypothetical 350-passenger battery electric bus, batteries with an energy density of 1700 Wh per kg constitute 17% of the payload.

This underscores the need for a nearly eightfold increase in the current pack energy density, from 250 Wh/kg to 1700 Wh/kg.

*(Please scroll down using arrows)

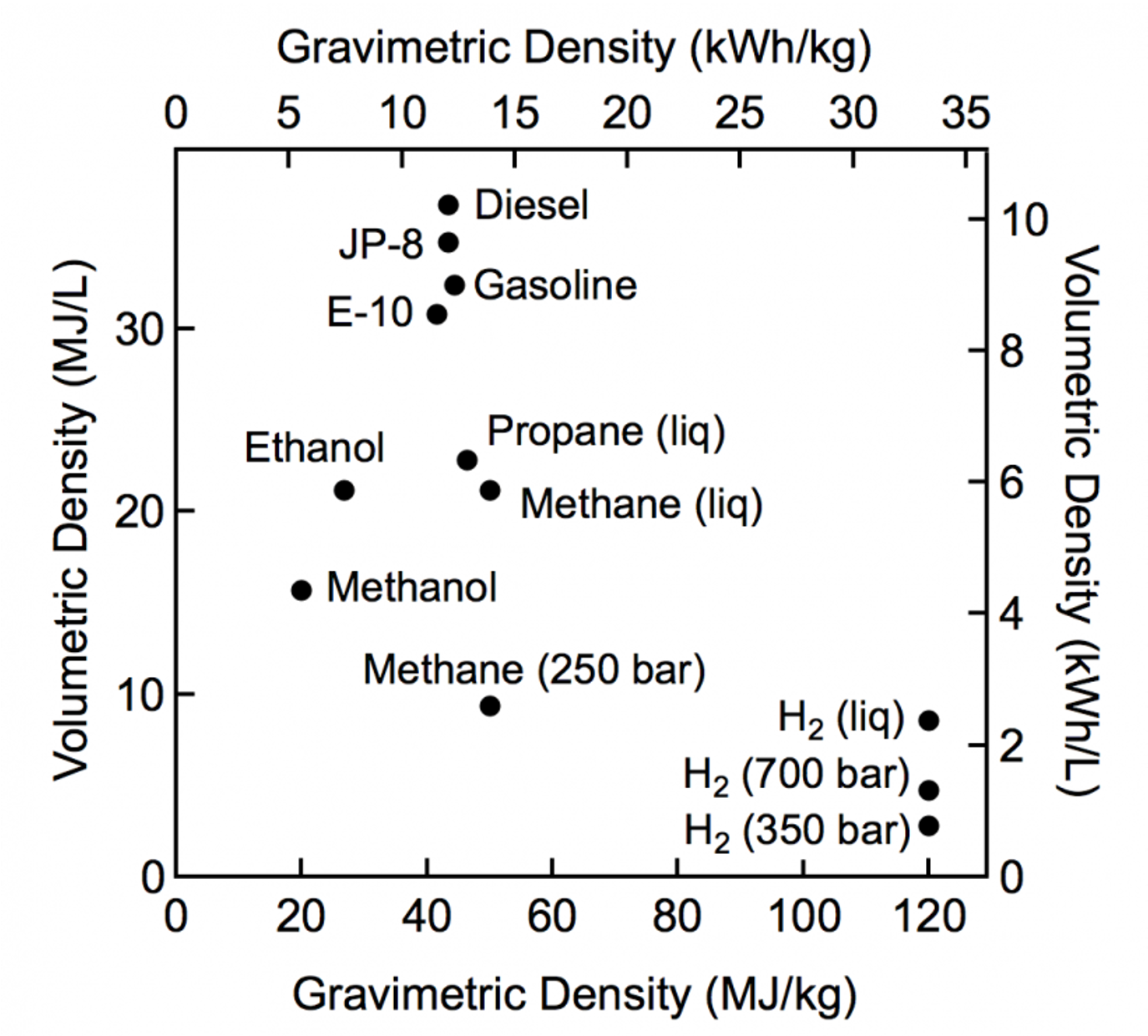

Challenges in Storage: Density and Safety

Hydrogen storage, in both its liquid and gaseous forms, presents notable challenges. These encompass safety concerns such as increased boil-off pressure and decompression waves.

Liquid Hydrogen experiences boil-off losses ranging from 0.3% to 1% daily. This necessitates carrying additional fuel to offset these losses. Moreover, both the compression and liquefaction processes of Hydrogen are energy-intensive.

Ammonia's challenges lie in its high toxicity, even at minimal concentrations. Methanol, on the other hand, has broader explosion limits and is toxic if ingested.

In a recent paper, Wolfram et al. (2022) pointed out that the scale of demand for Ammonia from Maritime transport could substantially alter the Nitrogen cycle

*(Please scroll down using arrows)

Our Solution

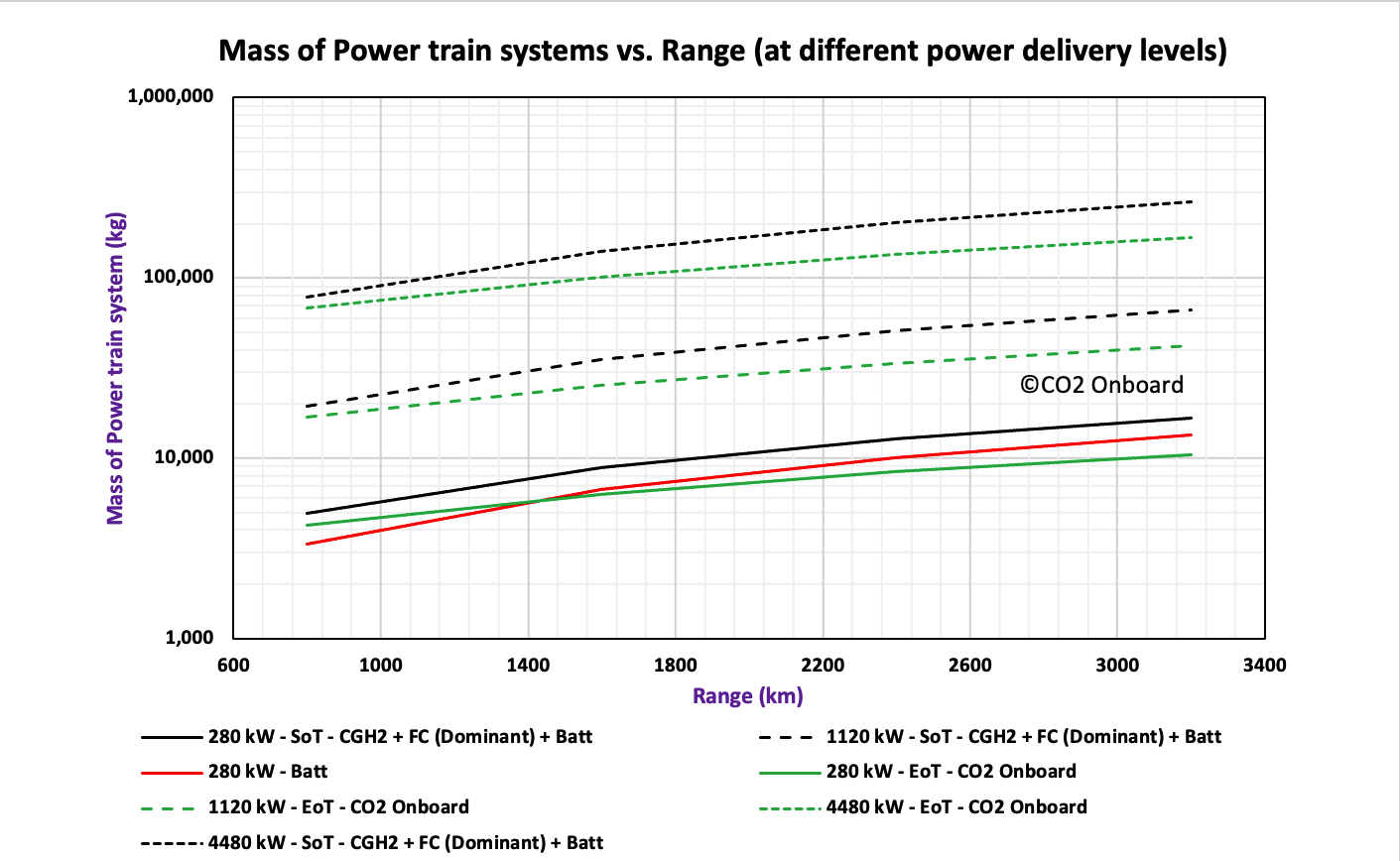

Our proposed solution running on Bio or Bio-E or E-Methanol can enable net-negative emissions while still retaining the powertrain mass advantage compared to Compressed Gas Hydrogen at 350/700 bar and Battery.

There are also other potential circularity, energy, cost, infrastructure and safety benefits with our solution.

*(Please scroll down using arrows)

Contact Us

Please leave your details here. We will get back to you shortly!